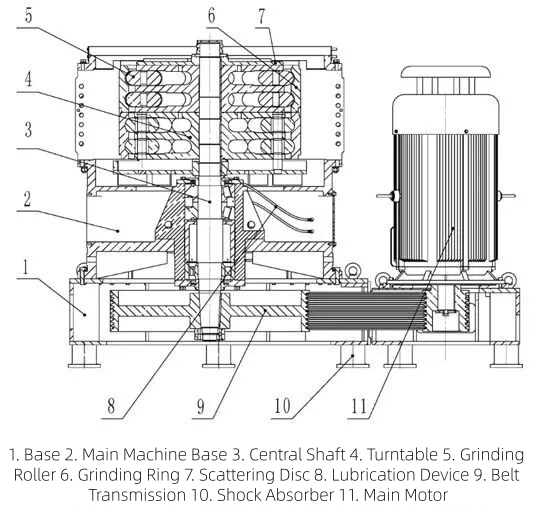

I. Structure of the Ring Roller Mill

The Ring Roller Mill is an ideal dry-processing equipment for producing superfine powders from non-metallic minerals. Its main components include the base, main machine base, central shaft, turntable, grinding rollers, grinding ring, scattering disc, lubrication device, belt transmission, shock absorber, and main motor.

II. Working Principle

The Ring Roller Mill operates on the principles of impact, compression, and grinding. There is significant clearance between the grinding ring (mounted on its bracket) and the pin shaft. As material passes through the gap between the grinding ring and the roller, it is pulverized by these combined forces. The crushed material then falls by gravity onto the scattering disc, which flings it into the airflow and up into the classification chamber. Qualified fine powder passes through the classifier wheel into the downstream collection system, while coarse material is thrown against the diversion ring/liner and falls back into the grinding chamber for repeated processing. In a double-layer grinding ring mill, material undergoes a secondary crushing stage as it passes through the gap of the second layer.

III. Applications in the Non-Metallic Mining Industry

Ring Roller Mills are primarily used for the superfine grinding of minerals such as calcite, dolomite, limestone, marble, and wollastonite.

Taking calcite as an example, the grinding process involves four main stages:

1. Raw Material Crushing: Large calcite rocks are crushed by a crusher to a feed size (15mm-50mm) suitable for the mill.

2. Grinding: The crushed calcite is elevated to a storage hopper, then fed uniformly and quantitatively by a feeder into the mill’s grinding chamber.

3. Classification: The ground powder is classified by the integrated classification system. Oversized particles are returned to the main chamber for regrinding.

4. Product Collection: Powder meeting the fineness specification is carried by the air stream through pipes into the filter for separation and collection. The collected final product is discharged and conveyed to a product silo, ready for bulk tanker loading or automated bagging.

IV. Advantages of the Ring Roller Mill

Ring Roller Mill Parameters

| Model | SRM800 | SRM1000 | SRM1250 | SRM1680 |

| Feed Size (mm) | < 10 – 20 | < 10 – 20 | < 10 – 20 | < 10 – 20 |

| Moisture (%) | < 5% | < 5% | < 5% | < 5% |

| Mill Motor (kw) | 75 | 132 | 185 | 315 |

| Classifier Motor (kw) | 15 – 18.5 | 22 – 30 | 37 – 60 | 55 – 92.5 |

| Fan Motor (kw) | 37 – 45 | 55 – 75 | 75 – 110 | 132 – 180 |

| Product Finess (mesh) | 325 – 2500 | 325 – 2500 | 325 – 2500 | 325 – 2500 |

| Product Capacity (T) | 0.5 – 4.0 | 1.0 – 8.0 | 2.0 – 12 | 3.0 – 20 |

1. Cost-Effective & High ROI: Compared to large-scale complete plant systems, it can save nearly half the investment. For instance, establishing a 10,000 tons/year superfine powder production line requires an investment of only 500,000 RMB with a Ring Roller Mill, representing 60% savings compared to other options.

2. High Classification Accuracy: The internal classification device, featuring a uniquely structured classifier wheel. It ensures excellent grading efficiency and freedom from large particle contamination.

3. Low Energy Consumption: For producing ground calcium carbonate powder with a fineness of D97 < 10μm, power consumption is approximately 95 kW·h/t, making it a notably energy-efficient and modern solution.

4. Stable & Reliable Operation: The main shaft is driven by a gear reducer, ensuring low energy consumption, high efficiency (>96%), and smooth operation.

5. High Specific Surface Area: Specific Surface Area (SSA) is a key indicator of the activity of superfine calcium carbonate powder. The Ring Roller Mill can produce superfine powders with an SSA ranging from 2.24 m²/g (D97=10μm) to 3.04 m²/g (D97=4μm), significantly higher than other domestic equipment.

V. Key Considerations for Processing Fine Powder

1. Maintain Feed and Discharge Balance: The contact between the grinding ring and roller is non-rigid, cushioned by a layer of material. The large clearance means the main motor current won’t spike and trip due to overfeeding. During operation, the feed rate should be increased gradually while ensuring product fineness. Excessive feeding disrupts balance, reduces output, and can lead to coarse particle carryover and uneven product size.

2. Allow Adequate Post-Feed Run Time: After stopping the feeder, material remains in the grinding chamber. It’s crucial to run the mill for approximately 5 more minutes to ensure all material is processed and discharged, facilitating a smooth next start-up. In case of a sudden power outage, manually rotate the motor coupling before restarting; if severely jammed, clear the chamber before starting.

Epic Powder Machinery

For exceptional results in non-metallic mineral powder processing, the advanced design principles and robust construction of Ring Roller Mills are key. If you are looking for reliable, efficient, and cost-effective grinding solutions to produce high-quality superfine powders, Epic Powder is your ideal partner. Our expertise and advanced milling technologies are designed to meet your specific production needs and help you achieve a competitive edge in the market. Contact Epic Powder today to discover how we can optimize your powder processing operations.

“Thank you for reading. I hope my article helps. Please leave a comment down below.

You may also contact Epic Powder online customer representative for any further inquiries.”

— Emily, Chen