How to Achieve Consistent Ultra-Fine Calcium Carbonate Powder with Ring Roller Mill Technology

Struggling with inconsistent GCC powder? Discover how Epic Powder Machinery’s Ring Roller Mill delivers energy-efficient, precise grinding for calcium carbonate from 150 to 2500 mesh. Boost your product quality in plastics, paints, and paper. Request a quote today! Ground Calcium Carbonate (GCC) is the lifeblood of modern industry. From enhancing the strength and brightness of paper and plastics to improving the opacity and durability of paints and coatings, its applications are vast and critical. However, for GCC producers, a significant challenge persists: how to consistently and efficiently achieve the precise, ultra-fine powder specifications that end-market industries demand. Traditional grinding methods often lead to inconsistent particle size distribution, high energy consumption, and the risk of metal contamination, which can compromise product quality and profitability.

The solution lies in adopting advanced milling technology designed specifically for these challenges. At Epic Powder Machinery, we specialize in harnessing the power of Ring Roller Mill technology to transform your calcium carbonate processing, delivering unparalleled precision, purity, and efficiency.

Why Fine Grinding is Critical for Calcium Carbonate

The Power of Precision: Why Calcium Carbonate Particle Size Matters

In the world of GCC, size isn’t just a number—it’s the defining factor of performance. The particle size and its distribution directly influence the functional properties of the final product in profound ways:

In Plastics: Finely controlled GCC (e.g., 800-1250 mesh) acts as more than just a filler. It improves tensile and impact strength, enhances stiffness, and provides a superior surface finish. Inconsistent coarse particles can create weak spots and defects.

In Paints & Coatings: Ultra-fine GCC (1250-2500 mesh) is key to achieving excellent hiding power, stable gloss, and optimal dispersion. It influences rheology, preventing sagging and ensuring a smooth, durable film.

In Paper: GCC fillers improve paper’s brightness, opacity, and printability. A tightly controlled particle size distribution ensures smoothness and reduces wear on paper machine wires.

Ultimately, consistent and controllable grinding is not an option; it’s a prerequisite for producing high-value GCC and maintaining a competitive edge.

Ring Roller Mill Explained: Engineered for Perfect Calcium Carbonate

Inside Epic’s Ring Roller Mill: A Superior Grinding Mechanism

So, how does a Ring Roller Mill achieve what other mills cannot? The secret is in its unique grinding principle centered on compression and shear, rather than impact.

Here’s a breakdown of the process:

- Feeding & Distribution: Raw calcium carbonate feed is uniformly fed into the grinding chamber.

- Multi-Layer Grinding: The heart of the system features a rotating grinding ring and multiple freely rotating rollers. Centrifugal force presses these rollers against the ring, creating a powerful compression zone. The material is crushed and ground between these surfaces as it passes through multiple layers.

- Instant Classification: The finely ground powder is carried upward by an airflow into an integrated dynamic classifier. This classifier acts as a precision gatekeeper, allowing only particles that meet the target fineness to pass through. Oversized particles are rejected and returned to the grinding chamber for further processing.

- Collection: The finished, on-spec powder is then collected in a downstream cyclone and bag filter system.

This closed-loop, dry-process system is engineered from the ground up for minerals like calcium carbonate.

The Top 6 Benefits of Choosing a Ring Roller Mill for Calcium Carbonate

Beyond Grinding: The Tangible Benefits for Your GCC Operation

Investing in an Epic Powder Ring Roller Mill translates into direct, measurable advantages for your production line.

1. Unmatched Energy Efficiency

The “material-bed” comminution principle of a ring roller mill is inherently more efficient than the ball-on-ball impact of a ball mill or the high-speed impact of some other mills. By utilizing compression to fracture particles, it significantly reduces energy waste, directly slashing your operating costs per ton of GCC produced.

2. Exceptional Product Purity

For high-value GCC applications where whiteness and purity are paramount, metal contamination is a major concern. Our mills offer the option of ceramic or polyurethane liners for the grinding parts. This ensures an absolutely iron-free grinding process, preserving the natural brightness of your calcium carbonate and opening doors to premium markets.

3. Precise Particle Size Control

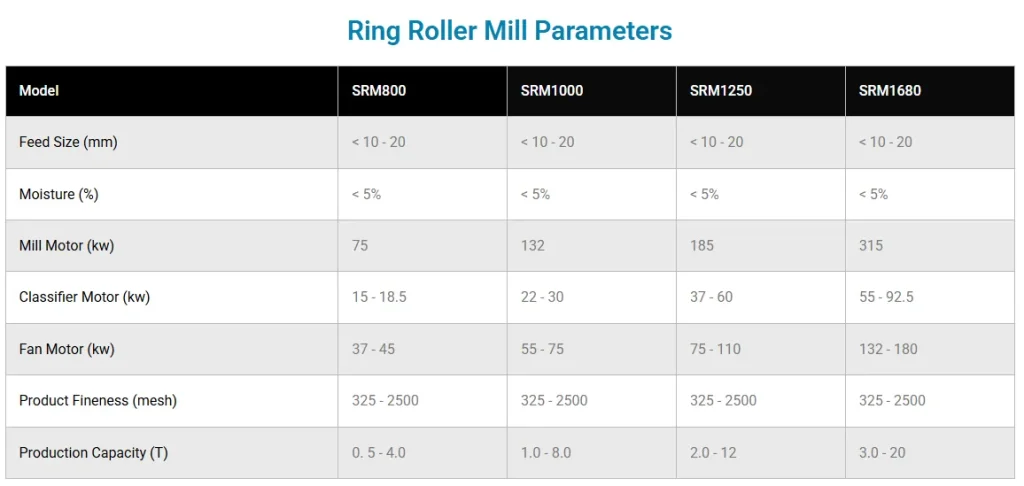

With its integrated high-precision dynamic classifier, our Ring Roller Mill offers unparalleled control over your final product. You can easily adjust the fineness from a coarse 150 mesh (100μm) to an ultra-fine 2500 mesh (5μm) simply by changing the classifier’s speed. This flexibility allows you to produce multiple GCC grades with a single machine.

4. Low Noise and Stable Operation

The grinding mechanism generates less noise and vibration compared to impact mills. This creates a better working environment and ensures smoother, more stable long-term operation with reduced stress on the equipment’s structure.

5. High Reliability and Low Maintenance

Built with robustness in mind, the core grinding components are designed for longevity. The system’s simplicity and durability translate into higher uptime, reduced frequency of maintenance, and lower spare parts costs over the machine’s lifecycle.

6. Versatility for Various GCC Grades

Whether you are processing marble, limestone, or chalk, the Epic Ring Roller Mill is highly adaptable. Its adjustable parameters allow it to handle variations in feed material and consistently produce the exact GCC grade required by your customers, making your operation incredibly agile.

The Epic Powder Promise: More Than Just a Machine

Your Partner in Calcium Carbonate Processing Excellence

At Epic Powder Machinery, we understand that you need more than just a piece of hardware—you need a reliable partner for your success. Our commitment goes beyond manufacturing:

Deep Application Knowledge: Our engineering team possesses extensive experience in the calcium carbonate industry. We provide insights not just on the machine, but on the entire process to optimize your output.

Customized Solutions: We know one size does not fit all. We work with you to analyze your raw material and product goals, tailoring a mill configuration that perfectly fits your needs.

Global Support & Service: From installation and commissioning to ongoing maintenance and spare parts supply, our global network ensures you have the support you need, when you need it.

Ready to transform your calcium carbonate production, enhance your product quality, and reduce your operating costs?

Contact our experts at Epic Powder Machinery today for a free consultation and a custom solution quote. Let us demonstrate how our Ring Roller Mill technology can become your most valuable asset.

Epic Powder

In a competitive market where product quality and cost-efficiency are paramount, the choice of grinding technology is decisive. The Ring Roller Mill stands out as the modern, intelligent solution for producing high-quality Ground Calcium Carbonate. It offers a powerful combination of precision, purity, and profitability that traditional mills cannot match. By partnering with Epic Powder Machinery, you are not just purchasing a mill; you are investing in a future of consistent excellence and sustainable growth for your business.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Posted by Jason Wang, Senior Engineer