In the deep processing of calcium carbonate, the ring-roller mill plays a central role as a core grinding equipment. It provides the key technical support for transforming ground calcium carbonate (GCC) from ordinary ore into high-value-added ultrafine powder. Its efficient, energy-saving, and controllable dry ultrafine grinding capability directly determines the final product’s particle size, morphology, dispersibility, and application performance. This plays a decisive role in enhancing the competitiveness of calcium carbonate in high-end fields such as plastics, paper, and coatings. Today, we will discuss in detail from four perspectives: process positioning, technical advantages, product value, and industry promotion.

Process Positioning

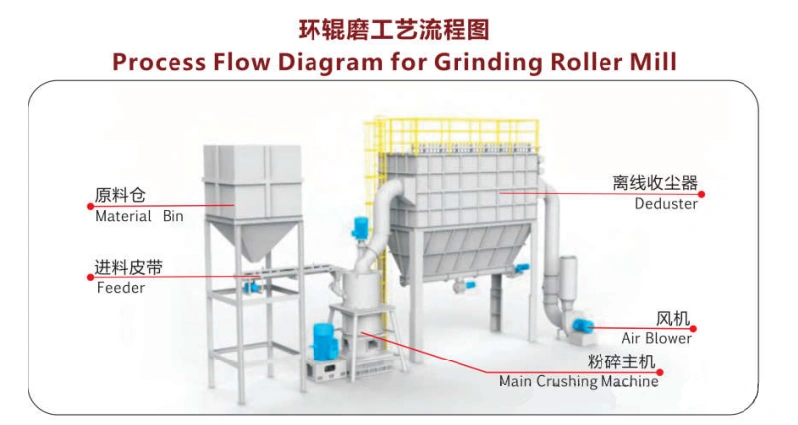

Raw Ore → Crushing → Ring-Roller Mill Ultrafine Grinding → Classification → Finished Product Collection → (Optional) Dry Surface Modification

The entire process is fully dry and operates in a closed circuit, requiring no drying step. This aligns perfectly with the processing requirements for calcium carbonate: “low moisture, high whiteness, no pollution.” In the production process for ground calcium carbonate, there are primarily four technical routes: Raymond mills, ball mills, vertical mills, and ring-roller mills. However, the ring-roller mill is undoubtedly the most widely adopted process. According to industry statistics, over 80% of domestic ultrafine GCC (D97 ≤ 10 μm) production lines utilize the ring-roller mill process.

| Equipment Type | Suitable Fineness Range | Production Capacity Characteristics | Energy Consumption Level | Product Characteristics | Typical Application Scenarios |

| Raymond Mill | ≤ 325 mesh (D97 ≥ 45 μm) | Small to medium scale (1-10 t/h) | Moderate | Coarser particle size, wide distribution | Common fillers, building gypsum, primary chemical raw materials |

| Ball Mill + Classification System | 325 mesh – 6500 mesh | Medium to large scale (expandable by parallel configuration) | High (Severe over-grinding) | Can reach nano-scale, but particle shape is irregular | High-purity ultrafine calcium, electronic materials, wet-process precursors |

| Vertical Roller Mill (VRM) | 80 mesh – 1250 mesh | Large scale (10-100+ t/h) | Low (20-30% more energy-efficient) | Uniform particle size, suitable for bulk products | Cement raw meal, desulfurizing agents, large-scale production of ordinary ground calcium carbonate (GCC) |

| Ring Roller Mill | 325 mesh – 3250 mesh (D97 = 5-45 μm) | Small to medium batch (0.5-10 t/h) | Relatively low (better than ball mill) | Narrow particle size distribution, slightly rounded particle shape, high whiteness | High-value fillers for paper/coatings/plastics, pharmaceuticals, food-grade powders, high-grade desulfurizing agents |

Technical Advantages

1. Fine and Narrow Particle Size Distribution

Through multiple sets of grinding rollers and multi-layer grinding ring structures, combined with a variable frequency speed-regulating turbo classifier, the ring-roller mill can stably produce powders with: D97 = 5–45 μm (325–2500 mesh); and a particle size distribution Span value < 1.2, far superior to Raymond mills (Span > 1.8). This is crucial for applications like plastic masterbatches and high-end coatings that require high filler loading and good rheology.

2. Optimized Particle Morphology

Under the compound force field of compression and shearing, calcium carbonate particles are broken into near-spherical or short-column shapes with reduced edges and corners and a moderate specific surface area. This is beneficial for improving compatibility with polymer matrices, reducing system viscosity, and enhancing processing flow. In contrast, impact-based pulverization tends to produce flaky or needle-like particles, which adversely affect dispersion.

3. Low Iron Contamination, High Whiteness Retention

High-end ring-roller mills utilize high-chromium alloy or ceramic wear-resistant parts, resulting in extremely low iron migration (<50 ppm). The whiteness of the finished product can reach over 95%, meeting stringent standards for paper, food-grade plastics, etc.

4. Significant Energy Saving and Consumption Reduction

When producing 1250-mesh GCC, the specific power consumption of a ring-roller mill is approximately 75–85 kWh/t. It is over 30% lower than ball mill systems. The investment payback period is typically less than 2 years.

Product Value

According to an article titled “Yongfeng’s ‘Stone-to-Gold’ Alchemy” published by the Jiangxi Provincial Department of Ecology and Environment on November 24, 2025, Mr. Liu Weiqiang, head of the R&D center at Jiangxi Guangyuan Chemical Co., Ltd., stated: “This traditional ore for cement sells for USD 11 per ton, while this special ore for nano-calcium carbonate, after processing into nano-grade material, can fetch up to USD 430 per ton.” This clearly shows that processing ordinary calcium carbonate into nano-grade high-end materials using ring-roller mills significantly increases its value, giving the product broad prospects.

Industry Promotion

The widespread adoption of roller mill technology has directly driven the transformation of China’s calcium carbonate industry from extensive mining to deep processing:

• Yongfeng County Case: Leveraging ultrafine powder technologies like ring-roller mills, the county’s ore utilization rate increased from 50% to over 90%, forming a complete industrial chain from “mine → ultrafine powder → plastic masterbatch → end products.” In 2024, revenue from new materials reached 11.38 billion yuan.

• Enterprises like Guangyuan Chemical, based on ring-roller mill processes, have taken the lead in formulating the industry standard for “Ultrafine Ground Calcium Carbonate,” helping to standardize market order.

• Fully enclosed negative pressure operation combined with pulse-jet dust collection achieves “no dust overflow and low noise,” meeting the requirements for building “zero-waste factories.”

The ring-roller mill is not merely a pulverizing tool for calcium carbonate deep processing. It is a carrier for new quality productive forces. Through precise particle size control, excellent energy efficiency performance, and flexible process adaptability, it transforms low-cost ore into highly functional powder materials, supporting the upgrade demands of trillion-yuan downstream industries like plastics, paper, and coatings. In the future, with continuous advancements in intelligent control, wear-resistant materials, and classification technology, the core position of the ring-roller mill in the high-end, green, and customized development of calcium carbonate will be further solidified.

We hope this article provides you with valuable insights. The journey of exploring the powder world is long and fascinating. Epic Powder is committed to being your reliable companion along the way.

“Thanks for reading. I hope my article helps. Please leave a comment down below.

You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Jason Wang, Senior Engineer