If you’re aiming to produce consistent ultra-fine barite powder with precision, mastering the use of a ring roller mill is essential. In this guide, you’ll discover practical insights on how to optimize key mill parameters for stable, ultra-fine output—delivering the uniformity and efficiency today’s barite markets demand. Ready to elevate your barite grinding process? Let’s get into the details.

Understanding Barite and Its Applications

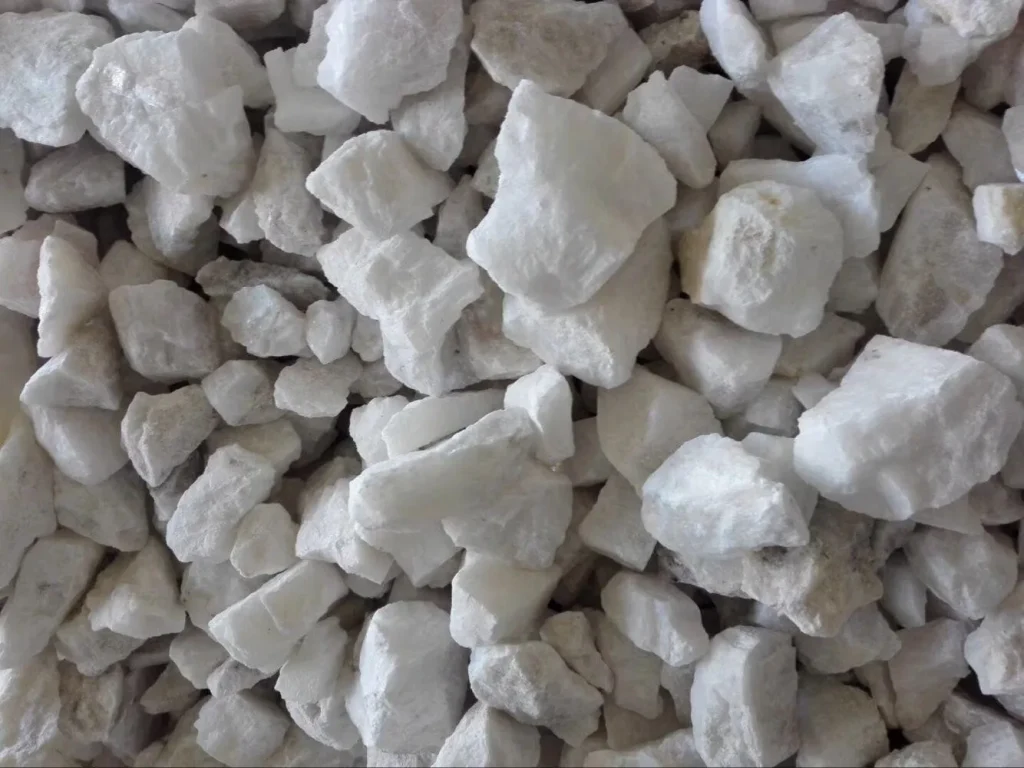

Barite, a mineral primarily composed of barium sulfate (BaSO₄), is known for its high density, chemical stability, and unique physical properties. These qualities make barite an essential material across various industries. Its dense and inert nature allows it to serve as an effective weighting agent, especially in oil and gas drilling muds, which accounts for 70-80% of the global barite demand. By increasing the mud’s weight, barite helps control well pressure, preventing blowouts and ensuring safety during drilling.

Beyond drilling muds, barite finds valuable use as a filler material in paints, plastics, and rubber products, where it improves brightness, durability, and smoothness. It also plays a critical role in radiation shielding applications, such as in medical imaging rooms and nuclear facilities, due to its ability to absorb X-rays and gamma rays. Additionally, barite is a key ingredient in pharmaceuticals and medical imaging, where its purity and fine particle size contribute to safety and performance.

Achieving an ultra-fine particle size in barite powder significantly enhances its effectiveness in all these applications. Ultra-fine barite grinding improves particle packing, dispersion, and surface area, which boosts the performance of drilling muds by providing better mud weight control and reduces settling. In fillers, the finer powder promotes uniformity and stronger bonding within the material matrix, enhancing product quality and longevity. For radiation shielding and medical uses, ultra-fine barite ensures consistent density and optimal barrier protection.

In , understanding barite’s chemical makeup and its core applications highlights why achieving consistent ultra-fine barite powder is vital. This ultra-fine particle size directly impacts key industries, making advanced grinding solutions like ring roller mills indispensable for meeting strict quality and performance standards.

The Evolution of Ring Roller Mills

Ring roller mills have come a long way from the traditional roller mills used decades ago. Initially designed for basic grinding tasks, these mills have evolved into sophisticated machines capable of producing ultra-fine powders, especially for minerals like barite. Modern ring roller mills now feature multi-layer grinding technology, which increases throughput by allowing material to be crushed in several stages within the same mill housing.

Another major advancement is precision classification systems integrated into the mill, which ensure a narrow particle size distribution (PSD) and consistent ultra-fine barite powder fineness down to 5-45 μm. These classifiers separate fine particles from coarse ones efficiently, saving energy and improving product quality.

In terms of efficiency, ring roller mills use energy-saving mechanisms that reduce power consumption significantly compared to older models. This makes them highly competitive against other grinding types like ball mills, Raymond mills, and jet mills. For processing non-metallic minerals such as barite, ring roller mills offer clear benefits including:

- Better control over ultra-fine particle size

- Higher grinding efficiency with lower energy use

- Less wear on components due to improved design

- Steadier output with less recirculation of oversized particles

If you want a deeper dive into how these innovations work specifically in the non-metallic mineral sector, the comprehensive guide to ring roller mills in non-metallic mineral powder processing provides solid insight. The evolution of ring roller mills reflects their growing importance in producing consistent ultra-fine barite and other powders efficiently and reliably.

How Ring Roller Mills Work for Ultra-Fine Grinding

Ring roller mills are specially designed for ultra-fine barite grinding, delivering a consistent particle size distribution between 5 and 45 microns. The core components include grinding rollers, grinding rings, a classifier, and an airflow system, each playing a crucial role in achieving ultra-fine powder processing.

The process starts with material feeding, where pre-crushed barite enters the mill. The grinding rollers apply multi-stage high pressure against the grinding rings, crushing the barite into finer particles. As the powder reaches the desired fineness, the built-in classifier separates coarse particles from ultra-fine barite, recirculating the larger ones for further grinding.

Simultaneously, the airflow system helps transport fine particles out of the mill and prevents overheating, maintaining the quality and consistency of the final barite powder. This combination of high-pressure grinding rollers and precise classification ensures a narrow PSD barite output, ideal for applications requiring consistent ultra-fine barite powder.

Key Factors for Achieving Consistent Ultra-Fine Barite Powder

To get consistent ultra-fine barite powder with a ring roller mill, several key factors must be managed carefully:

- Raw Material Preparation: Keeping the moisture content below 5% is crucial. Excess moisture can cause clogging and reduce grinding efficiency. Pre-crushing the barite to a uniform feed size improves mill throughput and helps maintain stable particle size distribution.

- Mill Parameter Adjustments: Fine-tuning roller pressure, classifier speed, and airflow rates plays a vital role in controlling barite powder fineness. Increasing roller pressure boosts grinding efficiency, while precise classifier speed ensures narrow PSD barite targeting specific micron sizes (5-45 μm). Optimized airflow helps separate fine particles and reduces over-grinding.

- Wear-Resistant Components: Barite’s abrasive nature demands grinding rings and rollers made from high-chromium alloys. Using these wear-resistant materials extends equipment life and maintains consistent output quality throughout production.

- Closed-Loop Systems: Incorporating a closed-loop airflow or dust collection system prevents contamination and keeps the ultra-fine powder clean. It also ensures uniformity across batches, which is essential for high-end applications like barite drilling mud powder.

Controlling these factors is the secret to stable, efficient ultra-fine powder processing, enhancing both barite filler applications and drilling mud performance with consistently fine and pure barite micronization. For more on optimizing grinding systems, see our overview of a high-efficiency roller mill for superfine powder up to 2500 mesh.

Optimization Tips and Best Practices for Ultra-Fine Barite Powder

To achieve consistent ultra-fine barite grinding with a ring roller mill, fine-tuning your process controls is key. Using intelligent PLC systems helps maintain stable fineness by automatically adjusting mill parameters like roller pressure and classifier speed in real-time. This ensures a narrow particle size distribution and consistent barite powder fineness.

Energy efficiency is another important factor. Ring roller mills are designed to reduce power consumption by up to 30% compared to traditional mills, thanks to optimized airflow systems and high-pressure grinding rollers. To maximize these savings, regularly monitor airflow rates and avoid over-grinding, which wastes energy and generates unnecessary fines.

Maintenance plays a vital role in keeping your mill running smoothly. Schedule regular inspections of wear-resistant grinding rings and rollers, focusing on lubrication and timely replacements to prevent unexpected downtime. This prolongs equipment life and keeps barite micronization efficient.

Common challenges include over-grinding, which leads to excessive dust emissions, and coarse particle recirculation that disrupts product uniformity. Installing closed-loop classification systems helps recirculate oversized particles back to the grinding chamber, ensuring only the ultra-fine powder is collected.

By combining precise process controls, energy-saving strategies, and diligent maintenance, you can consistently produce high-quality barite powder with a narrow PSD, meeting the demanding needs of drilling mud and filler applications.

For more insights on maintaining performance and wear resistance, exploring the role of different grinding media can also be valuable. Check out our detailed guide on types of grinding media balls for additional optimization tips.

Epic Powder’s Ring Roller Mill Solutions

Epic Powder’s SRM series ring roller mills stand out for their high efficiency and durable design, perfectly suited for ultra-fine barite grinding. These mills offer an adjustable fineness range from 325 to 2500 mesh, giving you full control over barite powder particle size for diverse applications.

Key Features:

| Feature | Benefit |

|---|---|

| Adjustable Fineness | Achieve consistent ultra-fine barite powder (5–45 μm) |

| Durable, wear-resistant parts | Long service life with less downtime |

| Energy-efficient design | Cuts power costs by up to 30% |

| Closed-loop airflow system | Minimizes dust and contamination |

Real-world production lines using Epic Powder’s ring roller mill have successfully produced barite powders with particle sizes finer than 800 mesh, maintaining a narrow particle size distribution for better performance in drilling muds, fillers, and other applications.

Benefits:

- Higher yield thanks to efficient grinding and classification

- Lower operational costs with energy-saving mechanisms and reduced maintenance

- Environmentally friendly with dust control and compliance features built in

For detailed insights on ultra-fine powder processing technologies, check out Epic Powder’s expertise on ring roller mill applications.

Epic Powder’s SRM series offers a reliable, cost-effective solution for industries demanding consistent ultra-fine barite powder with optimal performance and longevity.

Comparison with Other Grinding Technologies

When it comes to ultra-fine barite grinding, the ring roller mill stands out compared to other common grinding options like ball mills and vertical roller mills.

| Grinding Technology | Particle Fineness | Energy Efficiency | Suitability for Barite Powder | Maintenance & Wear |

|---|---|---|---|---|

| Ring Roller Mill | 5-45 μm, narrow PSD | High (up to 30% savings) | Ideal for ultra-fine non-metallics; consistent barite micronization | Uses wear-resistant grinding rings; easy maintenance |

| Ball Mill | Coarser, less uniform | Lower energy efficiency | Suitable for coarser grinding; less ideal for ultra-fine barite | High wear & longer maintenance times |

| Vertical Roller Mill | Moderate fineness | Moderate | Good for general minerals but less precise for ultra-fine barite | Complex structure, higher maintenance |

Why Choose Ring Roller Mill for Barite Processing?

- Superior Fineness & Consistent Particle Size Distribution: Ring roller mills deliver ultra-fine barite powder with a controlled particle size, essential for drilling mud and filler applications.

- Energy-Efficient Barite Mill: Compared to ball mills, ring roller mills consume less power, reducing operational costs significantly.

- Robust Wear-Resistant Components: Barite’s abrasive nature demands durable materials. Ring roller mills use high-chromium alloys to extend wear part life.

- Stable Operation for Ultra-Fine Powder Processing: Advanced classifiers and closed-circuit systems help maintain narrow PSD and prevent overgrinding or dust.

Given these advantages, if your goal is consistent, ultra-fine barite powder with optimized energy use and long-term reliability, a ring roller mill is the preferred choice over other grinding technologies.

Epic Powder

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Jason Wang, Senior Engineer