Ball Mill vs Roller Mill Comparison Energy Efficiency and Performance

Choosing between a Ball Mill vs Roller Mill can make all the difference in your plant’s efficiency and operational costs. Whether you’re involved in cement grinding, mineral processing, or powder manufacturing, understanding the key differences is critical to selecting the right equipment for your specific needs. In this post, you’ll get a straightforward comparison of these two grinding technologies—breaking down how they work, their performance, energy consumption, and cost implications—so you can confidently decide which mill fits your production goals. Let’s look into what sets Ball Mills and Roller Mills apart and why it matters for your operation.

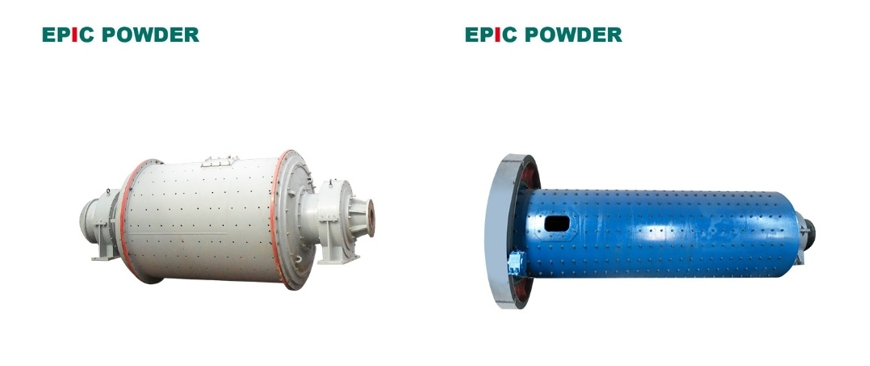

What is a Ball Mill?

A ball mill is a type of grinding mill widely used in industrial processes to crush and grind materials into fine powders. It operates on the principle of impact and attrition grinding, where the material is broken down by the collisions between the grinding media—typically steel balls—and the rotating cylinder’s inner surface. As the cylinder rotates, the steel balls tumble and cascade, grinding the material inside.

Key Components of a Ball Mill:

- Rotating Cylinder: A large horizontal drum that holds the grinding media and material.

- Grinding Media: Usually steel balls, which impact and abrade the material.

- Liners: Protective inner surfaces of the cylinder that protect the mill shell and improve the movement of the grinding media.

Ball mills are popular in various sectors like cement production, mining, and producing ultra-fine powders because they are versatile and reliable. They excel at grinding a wide range of raw materials, from ores to clinker, making them essential equipment in cement grinding and mineral processing plants.

What is a Roller Mill?

A roller mill, especially the vertical roller mill (VRM), is a popular grinding machine used in modern powder processing. Unlike ball mills that rely on impact and attrition, roller mills work on the principle of compression and shearing. Material is crushed as it’s pressed between heavy rollers and a rotating grinding table, effectively breaking down particles.

Key components of a vertical roller mill include the grinding table where the material sits, the rollers that press and grind the material, a separator to classify fine particles, and a hydraulic system that controls the pressure exerted by the rollers. This design offers improved efficiency and control over particle size distribution.

The VRM’s rise in popularity stems from its energy efficiency and ability to handle a variety of materials with different moisture contents. Today, vertical roller mills are widely used in cement grinding, mineral processing, and other sectors that require fine powder production. For those interested in detailed powder processing technology and equipment options, you might find insights on advancements in jet pulverizers helpful.

Core Differences: Side-by-Side Comparison

Understanding the Ball Mill vs Roller Mill differences helps pick the right mill for your operation. Here’s a clear rundown:

| Feature | Ball Mill | Roller Mill (Vertical Roller Mill) |

|---|---|---|

| Grinding Mechanism | Impact and attrition grinding: steel balls collide inside a rotating cylinder, breaking particles through impact and friction. | Compression and shearing: material is crushed and ground between rollers and a rotating grinding table, applying pressure and shear forces. |

| Design and Structure | Horizontal rotating cylinder filled with grinding media (steel balls). | Vertical setup with a stationary grinding table and rotating rollers pressing down. |

| Particle Size Distribution | Wider size range, sometimes less uniform; fine tuning is more challenging. | Narrower, more uniform particle size with better fineness control via separator settings. |

| Material Handling | Better for handling dry materials; some limitations with moisture. | Can tolerate higher moisture levels, often used with wet or damp materials. |

The ball mill is a tried-and-true option known for its simplicity and versatility, while the VRM is gaining traction for efficient fine powder production with lower energy use and finer control.

For detailed powder processing techniques, check out this guide on grinding sulfur to 300 mesh to see fine particle control in action.

Performance Comparison: Ball Mill vs Roller Mill

When comparing ball mills and roller mills, performance differences become clear across energy use, capacity, product quality, and environmental impact.

| Aspect | Ball Mill | Roller Mill |

|---|---|---|

| Energy Consumption | High – typically 20-50% more than roller mills. Ball mills rely on impact grinding, which consumes more energy. | Lower – 20-50% energy savings due to compression grinding and efficient design. Ideal for energy-conscious operations. |

| Production Capacity & Throughput | Moderate capacity. Throughput depends on mill size and speed but generally lower than roller mills. | Higher throughput thanks to continuous grinding and faster processing rates, especially in vertical roller mills (VRM). |

| Product Quality | – Good fineness, but with potential over-grinding and variation in particle size distribution. – Uniformity can be harder to control. | – Produces more uniform and consistent particle sizes. – Less over-grinding risk, better for achieving target fineness. |

| Noise Levels | Louder operation due to rotating drum and impact noise. | Quieter due to stable grinding pressure and enclosed design. |

| Environmental Impact | Higher power use means larger carbon footprint. Dust and noise pollution can be higher without proper controls. | More eco-friendly with better energy efficiency, lower emissions, and easier dust management. |

Key Takeaways

- Roller mills save energy significantly, often reducing operational costs.

- They offer higher throughput and more consistent quality in cement grinding and powder processing mills.

- Ball mills remain viable where capital investment is limited or material properties require impact grinding.

For modern industries seeking sustainability and efficiency, roller mills provide clear benefits, especially in mineral processing mills and advanced powder production.

Learn how to handle fine powder challenges effectively through technologies like roller mills by exploring modern solutions such as this nano powder preparation method.

Cost Analysis: Ball Mill vs Roller Mill

When looking at the initial capital investment, ball mills usually come out cheaper. Their design is simpler—a horizontal rotating cylinder with steel balls—making ball mills less costly to purchase and set up compared to the more complex vertical roller mills that require advanced components like hydraulic systems and separators.

However, the story changes when you consider operational and maintenance costs. Ball mills tend to incur higher expenses in terms of grinding media wear, frequent liner replacements, and downtime for repairs. Roller mills, thanks to their efficient compression and shearing action, generally experience less wear and require less maintenance. This often leads to significant long-term savings, despite their bigger upfront cost.

To sum up the total cost of ownership, roller mills may be more economical over time, especially for large-scale or continuous operations focused on energy efficiency and reduced downtime. Meanwhile, ball mills can be a cost-effective choice for smaller plants or less demanding applications. Carefully evaluating these factors is key when selecting grinding equipment that balances investment with ongoing operational costs.

For further details on optimizing powder processing equipment and maintenance, check out our technical milling guide for matcha powder micronization.

Advantages and Disadvantages of Ball Mill vs Roller Mill

When choosing between a ball mill and a roller mill, understanding their pros and cons helps decide which fits your needs best.

Ball Mill Pros and Cons

Pros:

- Simple, proven design with well-understood mechanics.

- Good for producing very fine powders due to impact and attrition grinding.

- Handles a wide range of materials, from soft to medium hardness.

- Lower initial capital investment compared to roller mills.

Cons:

- Higher energy consumption, typically 20-50% more than roller mills.

- More wear and tear on grinding media and liners, leading to increased maintenance.

- Larger footprint and generally noisier operation.

- Moisture tolerance is limited; wet material handling can be challenging.

Roller Mill Pros and Cons

Pros:

- Energy-efficient grinding, saving significant operational costs.

- Compact vertical design saves space and reduces noise.

- Better moisture handling, allowing wet and sticky materials processing.

- Produces uniform particle size with less over-grinding risk.

- Integrated hydraulic systems improve ease of operation and maintenance.

Cons:

- Higher upfront cost can be a barrier for small-scale operations.

- More complex maintenance due to hydraulic and separator systems.

- Not always optimal for ultra-hard materials; best suited for medium to low hardness.

Real-World Use Cases

- Ball mills often shine in industries needing ultra-fine powders like mineral processing or some cement grinding setups where initial investment costs need to be kept low.

- Roller mills dominate in modern cement plants and powder processing sectors where energy efficiency and throughput are critical. Their ability to handle varying moisture levels also makes them ideal in climates or processes prone to wet materials.

In , ball mills are reliable and cost-effective for straightforward grinding tasks, while roller mills offer efficiency and modern design advantages that suit large-scale, energy-conscious operations.

For further insights into optimizing powder quality and classification, integrating solutions like the advanced air separator systems can complement your grinding setup effectively.

Factors to Consider When Choosing Between Ball Mill and Roller Mill

Choosing between a ball mill and a roller mill depends on several key factors tailored to your specific operation. Here’s what to keep in mind:

- Material Properties: Hardness, moisture content, and abrasiveness play a huge role. Roller mills handle materials with moderate moisture better due to their compression grinding, while ball mills are often preferred for very hard or abrasive materials because of impact and attrition grinding.

- Production Scale and Output: If you’re running a large-scale operation with high throughput demands, roller mills typically offer higher capacity and more efficient powder processing. Ball mills may be suited for smaller batches or ultra-fine grinding needs.

- Energy Costs and Sustainability: Roller mills generally consume 20-50% less energy, making them appealing for businesses prioritizing energy efficiency and sustainability goals. Ball mills often have higher energy use and may impact operating budgets over time.

- Space Constraints and Installation: Roller mills have a vertical design that can save valuable floor space, which matters if your plant layout is tight. Ball mills require more horizontal space due to their large rotating cylinders.

- Integration with Existing Plant Systems: Consider how easily either mill can be integrated with your current setup, including material handling, feeding systems, and downstream equipment. Roller mills are often favored in modern plants with automated controls.

Balancing these factors will help you select the right grinding mill that fits your operational needs, budget, and long-term goals. For insights on grinding media and modifiers to optimize powder properties post-grinding, explore our detailed guide on the roles of dispersants and modifiers in powder modification.

Industry Applications

Ball mills and roller mills play vital roles across several key industries, each maximizing their unique strengths.

- Cement Grinding: Both ball mills and vertical roller mills (VRMs) are widely used for grinding raw materials and clinker in cement production. Ball mills have traditionally dominated, but VRMs are gaining ground due to better energy efficiency and finer particle size control. VRMs offer consistent output and reduce operational costs in modern cement plants.

- Mining and Mineral Processing: Ball mills are reliable when it comes to grinding ores for mineral extraction, thanks to their robust impact and attrition mechanism. Roller mills are increasingly preferred when dealing with abrasive materials and higher throughput requirements, especially where precise particle size distribution is critical for downstream processes.

- Ultra-Fine Powder Production: Roller mills excel in producing ultra-fine powders required in industries like chemicals and pharmaceuticals due to their gentle compression grinding and better moisture handling. Ball mills can achieve fine grinding but may risk over-grinding, impacting product uniformity.

- Other Sectors: Both mills find use in various powder processing applications, including food additives, pigments, and advanced materials production. The choice depends on factors such as material hardness, moisture content, and desired particle size.

Successful Implementations

Leading manufacturers worldwide have adopted VRMs in new cement plants to cut energy consumption by up to 40%, showcasing a clear advantage over conventional ball milling. Mining operators have integrated roller mills to improve throughput while minimizing wear parts and downtime. For ultra-fine grinding, companies often combine roller mills with classification systems to meet stringent product specifications efficiently.

For more on optimizing powder processing and drying in industrial settings, exploring high-performance ultrafine grinders and drying dispersing techniques can provide valuable insights.

In , selecting between ball mill and roller mill depends heavily on the application, desired product quality, and operational goals, given their distinct advantages across industries.

FAQs: Ball Mill vs Roller Mill

Which mill is more energy-efficient?

Roller mills, especially vertical roller mills (VRM), are generally more energy-efficient than ball mills. They can reduce energy consumption by 20-50% due to their grinding mechanism, which uses compression and shearing rather than impact and attrition. This efficiency makes roller mills a popular choice in industries aiming to cut operational costs and carbon footprints.

Can roller mills handle wet materials?

Yes, roller mills can handle materials with higher moisture content better than ball mills. Their design allows for efficient grinding and drying simultaneously, making them suitable for damp or sticky raw materials common in mineral processing and cement grinding.

What about maintenance requirements?

Ball mills usually require more frequent maintenance due to wear and tear on grinding media (steel balls) and liners caused by continuous impact. Roller mills, with fewer moving parts and a different grinding approach, tend to have lower maintenance costs but still need regular checks on rollers, hydraulic systems, and separators. Choosing between the two should factor in maintenance availability and costs relative to production goals.

For more on how different mills handle fine powder production and maintenance, check out our insights on ultrafine maltodextrin production.

Epic Powder

Epic Powder is specialized in fine powder processing technology for mineral industry, chemical industry, food industry, pharama industry, etc. Our team has more than 20 years experience in Various powders processing and had ever designed and installed the biggest Jet Mill Line for ultra-fine barite powder production line in China. We are a most professional supplier of powder processing projects, especially powder milling, powder classifying, powder dispersing, powder classifying, powder surface treatment and waste recycling. We supply consultancy, testing, project design, machines, commissioning and training.

“Thanks for reading. I hope my article helps. Please leave a comment down below.

You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Posted by Jason Wang, Senior Engineer