Fine calcium carbonate powder is one of the most versatile and widely used industrial minerals on the planet. Found in products ranging from high-gloss paper and durable plastics to sophisticated pharmaceuticals and premium paints, its quality and fineness directly impact performance. But producing fine calcium carbonate powder to precise specifications demands more than just grinding, it requires the right ring roller mill technology.

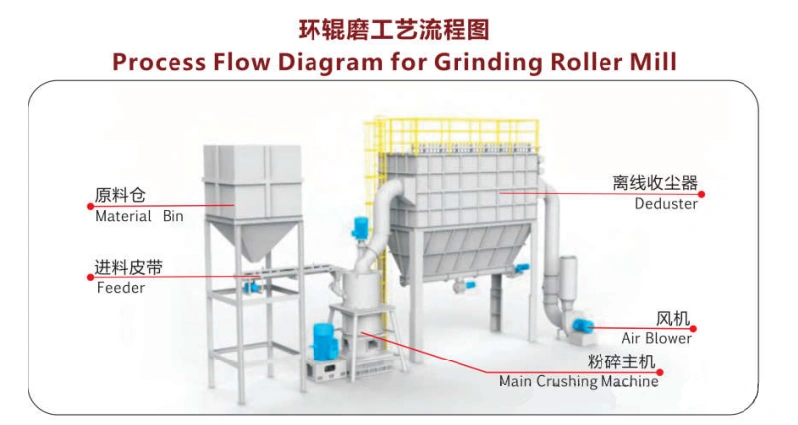

Unlike traditional grinding systems, a ring roller mill operates on the principle of compression and shearing. Raw material is fed into a grinding chamber where multiple rollers, pressed outward by centrifugal force, rotate against a stationary grinding ring. The material is crushed, ground, and then carried by an air stream to an integrated classifier. Oversized particles are rejected back to the grinding zone, while fine powder meeting the target size passes through for collection. This closed-circuit, mechanical grinding process is uniquely suited for achieving the tight particle size distributions and high brightness levels required for high-value calcium carbonate products.

Why Use a Ring Roller Mill for Calcium Carbonate?

While ball mills and Raymond mills have been industry staples, the ring roller mill offers distinct advantages for modern, high-specification production. For ultra-fine grinding (above 600 mesh or 25µm), ring roller mills provide superior energy efficiency as their grinding mechanism directly targets particle size reduction with minimal wasted energy on friction or noise. They generate less heat than ball mills, which is critical for preserving the crystal structure and brightness of calcium carbonate. Furthermore, their integrated dynamic classifiers allow for real-time, precise adjustments to fineness—from coarse fillers at 200 mesh to ultrafine powders at 2500 mesh—without stopping production. This versatility and control make them a superior choice for consistent, high-quality output.

What are the key factors affecting the fineness and output of calcium carbonate in a ring roller mill?

Achieving optimal results is a balance of several interconnected factors. First is raw material preparation: the moisture content must be strictly controlled (typically below 1%) to prevent clogging and ensure efficient grinding. The feed size should be pre-crushed to a uniform, small dimension (often ≤10mm). Second, machine parameters are crucial. The grinding pressure between the rollers and the ring determines the crushing force, while the rotation speed affects throughput. The most critical control point is often the classifier speed. A higher classifier rotor speed allows only finer particles to pass, directly increasing product fineness. Finally, the system airflow must be optimized to efficiently transport ground material, provide cooling, and maintain stability in the grinding circuit.

Benefits of This Production Method

Utilizing a ring roller mill for fine calcium carbonate production translates into significant competitive and operational benefits. The most immediate advantage is the creation of a high-value product with a uniform, narrow particle size distribution, which enhances performance in downstream applications like improved opacity in paper or impact strength in plastics.

Operationally, the system offers remarkable energy efficiency, consuming significantly less power per ton of product than traditional mills, leading to lower production costs and a reduced carbon footprint. The dry, enclosed process is also environmentally superior, featuring minimal dust emissions and lower noise levels.

Furthermore, the technology provides exceptional production flexibility. Manufacturers can quickly switch between different fineness grades (e.g., from a 400-mesh filler to an 800-mesh functional powder) to meet diverse customer demands without major equipment changes. This results in enhanced material properties for end-users, including higher brightness, better dispersion, and increased chemical compatibility.

A Detailed Step-by-Step Guide

Step 1: Raw Material Preparation

Begin with high-purity limestone (CaCO3 content >98%). Use a jaw crusher and hammer mill to pre-crush the feedstock to a uniform size of ≤10mm. Crucially, pass the material through a dryer (like a rotary or flash dryer) to reduce moisture content to below 1%. Perform an initial analysis of the raw material’s hardness and chemical composition.

Step 2: System Setup

Select a ring roller mill model with a capacity and fineness range matching your production goals. Ensure the system is fully integrated with a high-efficiency cyclone collector, a pulse-jet bag filter for final dust collection, and, most importantly, a precision turbo classifier. Before operation, conduct a thorough mechanical check of the grinding rollers and rings for wear and clear the entire pipeline.

Step 3: Grinding & Classification Parameter Calibration

Start the system’s main fan to establish airflow. Initiate the grinding roller assembly and set the hydraulic pressure to achieve the desired grinding force. Power on the classifier and set its rotor speed based on your target fineness (higher RPM for finer powder). Adjust the feed rate using a screw conveyor to a steady, optimal flow that matches the grinding capacity.

Step 4: Process Operation

Start the system in the correct sequence: fan → classifier → grinder → feeder. Continuously monitor the amperage of the main motor—a stable current indicates stable grinding conditions. Use a laser particle analyzer to take periodic samples and check the particle size distribution (e.g., D97, D50). Monitor the temperature at the mill outlet to ensure effective cooling.

Step 5: Product Collection

The fine powder is separated in the cyclone and bag filter. Collect the product in sealed silos or big bags immediately to prevent moisture absorption from the air. For certain applications, the powder may undergo surface modification (coating with stearic acid, for example) in a subsequent mixing step to enhance its properties for plastics or rubber.

Step 6: Systematic Maintenance

Establish a routine maintenance schedule. Regularly inspect and record the wear on grinding rollers and rings, replacing them as a set to maintain balance. Clean or replace filter bags as needed to maintain suction. Lubricate bearings and drives according to the manufacturer’s specifications, and periodically calibrate the classifier for accuracy.

Practical Results from the Field

Case 1: Enabling High-Performance Paint Formulations

A European coating manufacturer invested in a ring roller mill to produce ultrafine (2500 mesh) calcium carbonate for a new line of high-gloss, low-VOC paints. The mill’s precise classification produced powder with such a tight size distribution that it improved product brightness to 97% ISO and enhanced dispersion in the resin matrix. This allowed the formulators to reduce titanium dioxide content by 8%, achieving significant cost savings without sacrificing quality or opacity.

Case 2: Achieving Sustainable Production Goals

A North American producer focused on sustainability implemented a ring roller mill system with a fully closed-circuit design and advanced filtration. The plant reduced its particulate emissions to below 10 mg/m³, well within regulatory limits. Furthermore, the efficient process design led to zero process wastewater discharge and a material utilization rate exceeding 95%, turning their fine calcium carbonate roller mill line into a model of eco-efficient manufacturing.

Epic Powder

Epic Powder is specialized in fine powder processing technology for mineral industry, chemical industry, food industry, pharama industry, etc. Our team has more than 20 years experience in various powders processing. We are a professional supplier of powder processing projects, especially powder milling, powder classifying, powder dispersing, powder classifying, powder surface treatment and waste recycling. We supply consultancy, testing, project design, machines, commissioning and training.

“Thanks for reading. I hope my article helps. Please leave a comment down below.

You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Posted by Emily Chen, Senior Engineer