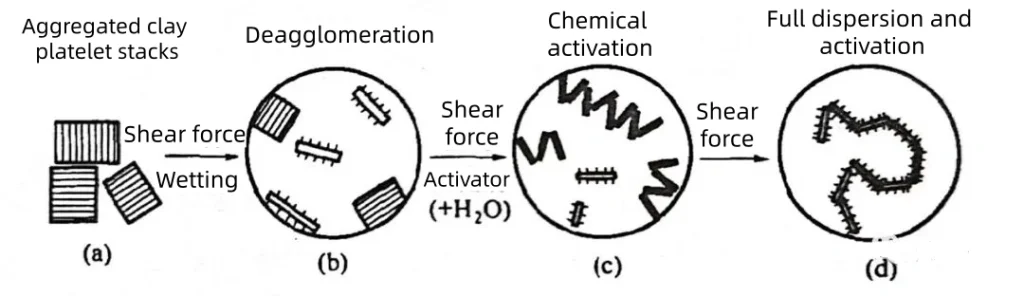

Organic bentonite rheological additives appear as powdered substances. Microscopically, they consist of agglomerated stacks of clay platelets, as shown in Figure (a) below. Both sides of these clay platelets are agglomerated with a large number of organic long-chain compounds. These organic long-chain compounds enhance compatibility with coating resins. The quantity and type of these organic long-chain compounds determine the suitability of the organic bentonite for different coating systems, such as low-polarity, medium-polarity, high-polarity, medium-high polarity, and universal systems. Epic Powder’s bentonite roller mill grinding solution can improve product consistency, and meet the requirements of various applications.

Gel Formation Mechanism: The Role of Water

After dispersion and activation, the hydroxyl groups on the edges of adjacent platelets are connected by water molecules, forming a thixotropic network structure, which macroscopically presents as a gel state. Without water molecules, a strong gel structure cannot be formed. It is best to pre-gel organic bentonite before use and add the gel during the pigment feeding stage of the coating production process. The mechanism of organic bentonite pre-gelation is illustrated in the figure below.

The Pre-gelation Process: Step by Step

First, under shear force, the solvent or resin solution enters the capillary pores, wetting the agglomerated platelet stacks [Figure a], causing them to deagglomerate [Figure b]. At this point, the system’s viscosity increases significantly. An activator is added under shear conditions to increase the distance between the platelets [Figure c]. Continued shear force fully disperses the platelets, resulting in the activated thixotropic structure [Figure d], known as bentonite gel. In the pre-gel process, the role of the activator is to dissociate and disperse the bentonite platelets and introduce water into the hydrophobic organic solvent to ensure the hydrogen bond strength of the bentonite network. The most commonly used activators are low molecular weight alcohols, such as methanol or ethanol.

These should be used in combination with water, specifically by adding 5% water to 95% methanol or ethanol. Higher molecular weight alcohols (like propanol or butanol) have poorer activation effects. Low molecular weight ketones, especially acetone, can also serve as activators, but their strong odor and low flash point limit their use in industrial coatings. For low-odor, high-flash point activators, propylene carbonate can be used, with a flash point of 242°C and very little odor.

Activator Dosage: Getting it Right

The amount of activator must be appropriate. Insufficient amount means even high shear force cannot fully separate all platelets, leading to only partial platelet dissociation and insufficient gel strength. Excessive activator will migrate to the platelet edges, interfering with hydrogen bonds and weakening the gel strength. Generally, the recommended dosages for activators (based on bentonite weight) are as follows:

| Activator | Dosage (%) |

| Methanol-Water (95:5) | 33 |

| Ethanol-Water (95:5) | 50 |

| Propylene Carbonate | 33 |

| Propylene Carbonate-Water (95:5) | 33 |

| Acetone-Water (95:5) | 60 |

Using a mixture of 95% activator and 5% water yields the best activation results. Adding 5% water significantly increases the gel’s viscosity. For convenience, some specially modified organic bentonite rheological additives can be added directly during the grinding stage without needing pre-gelation. Different organic bentonites may require different activators and pre-gel formulas. An example of a commonly used and effective pre-gel formula in practice is provided in the table below:

| Material Name | Dosage (wt%) |

| Organic Bentonite | 10 |

| Xylene | 85 |

| Industrial Ethanol | 5 |

The preparation procedure is relatively simple. Add the bentonite to xylene under stirring, disperse uniformly, then add the ethanol, and stir for 5-10 minutes to obtain a paste-like, smooth-textured bentonite pre-gel. Generally, bentonite pre-gel should be prepared immediately before use in the production process, ideally right before the feeding stage. Prepared pre-gel should not be stored for extended periods.

Optimizing Production with Epic Powder Advanced Bentonite Roller Mill Grinding

For companies seeking to enhance their organoclay production process, investing in advanced grinding technology is crucial. Epic Powder‘s bentonite roller mills are engineered for high efficiency and consistent particle size distribution, which is vital for achieving optimal performance of organic bentonite rheological additives. Our mills ensure effective deagglomeration and dispersion of clay platelets, contributing to superior gel formation and final product quality. By utilizing Epic Powder’s reliable and advanced bentonite roller mill grinding solutions, producers can streamline their operations, improve product consistency, and meet the demanding requirements of various applications.