How Ring Roller Mills Work & Key Tips for Superior Calcium Carbonate Powder

In the competitive world of industrial mineral processing, achieving consistent, ultra-fine calcium carbonate powder is crucial for product quality and market value. Traditional grinding methods often fall short, leaving producers with coarse grades, high energy costs, and limited profitability. This comprehensive guide explores the ring roller mill—an advanced dry-grinding technology revolutionizing ground calcium carbonate production. Discover how this technology can enhance your production line’s efficiency and output.

The ring roller mill operates on the principles of impact, extrusion, and grinding to pulverize materials. There is significant clearance between the grinding rings mounted on the ring carrier and their respective pins. As the carrier rotates with the main shaft, centrifugal force throws the grinding rings outward against the inner wall of the grinding race (the stationary ring). Pressed against this race, the rings also rotate around their own pins. Material passing through the gap between the rotating rings and the stationary race is subjected to impact, extrusion, and grinding, resulting in comminution.

The pulverized material falls by gravity onto a disc, which throws it into an airstream entering the classification chamber. Qualified fine powder passes through the classifier wheel into the downstream collection system, while coarse material is thrown against the inner wall of the separator and falls back into the grinding chamber for further milling. The grinding rings can be arranged in a single layer or upper/lower double layers. In a double-layer configuration, material is subjected to a second round of grinding as it passes through the gap of the second layer, ensuring thorough pulverization and a product meeting fineness specifications.

Key Considerations for Processing Fine Powder with a Ring Roller Mill

- The contact between the grinding ring and the grinding track is a non-rigid contact, as the gap is cushioned by a layer of pulverized material. Due to the large clearance between the grinding ring and the pin shaft, the system possesses a degree of flexibility (resilience). This ensures that the main motor current will not trip even if the feeding volume is excessive. During commissioning, the feed rate should be increased gradually while maintaining product fineness. If feeding is too rapid, the inflow and outflow of material become unbalanced; this causes the discharge speed to drop, results in the carry-over of coarse powder, and leads to inconsistent particle size distribution.

- After stopping the feed, material remains in the grinding chamber. It is crucial to continue operation until all residual material is fully processed and discharged before shutdown to ensure a smooth next start-up. Typically, run the mill for about 5 minutes after feed stops. In case of a sudden power outage, manually rotate the motor coupling by hand before restarting to ensure it moves freely. If severely jammed, clear the chamber before starting.

Advantages of Ring Roller Mill in Ground Calcium Carbonate (GCC) Processing

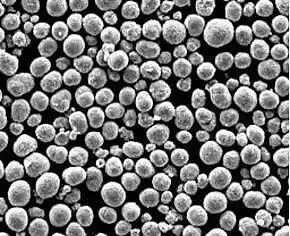

The ring roller mill is an ideal device for the dry production of GCC ultra-fine powder. Calcium carbonate, a crucial inorganic filler, is one of the three major fillers in chemical product manufacturing, with extensive applications. With China’s rapid economic development, requirements for the grade and fineness of calcium carbonate are increasingly stringent. In past years, Raymond mills were the primary equipment for domestic GCC processing, yielding relatively coarse products (generally 200-400 mesh). Although recent technological upgrades to Raymond mills have improved fineness to 600-800 mesh, they often still fail to meet user demands. This results in low product value-add and inefficient resource utilization. The new ring roller mill can produce fine powder with D97 < 10μm in a single pass. It offers numerous advantages:

Lower Investment, Higher Returns

Compared to large-scale sets equipment, investment is nearly halved. For producing ultra-fine GCC powder, some domestic processes use ball mills coupled with classifiers, achieving D97 < 10μm. Establishing a 10,000-ton annual production line with this method requires an investment of approximately USD200,000. Using one ring roller mill to produce the same fineness product at 10,000 tons annually requires only about USD70,000, saving 60% in investment.

High Classification Accuracy

Equipped with an internal classification device featuring a structured classifier wheel, it delivers excellent classification results free from large particle contamination. A mining company processed the same calcium carbonate ore using two methods: one with a vertical grinding line, the other with a ring roller mill. Product fineness tested by a UK-made Malvern particle size analyzer from both met the target (around D97 = 12μm).

Low Energy Consumption

The power consumption for producing GCC fine powder with D97 < 10μm is less than 100 kWh/t. It demonstrates significant energy savings compared to other machine types, positioning it as a new energy-efficient product.

Stable and Reliable Operation

The transmission main shaft of the series ring roller mill employs a reducer drive, offering low energy consumption and high efficiency (>96%). Comparative industrial trials between primary V-belt drive and reducer drive yielded these conclusions: The primary V-belt drive is simpler and lower cost, with 90-95% transmission efficiency. However, overload causes belt slippage, leading to unstable operation, directly affecting grinding performance. This results in more coarse particles in the powder, increasing the classifier load and risking motor burnout. To reduce slippage loss and the transmission ratio, the rotor speed must be increased, causing significant host vibration and noise. Adopting the traditional Raymond mill’s transmission structure (reducer-based) improves power utilization and overcomes these drawbacks. Although manufacturing cost increases slightly, equipment operation becomes more reliable, and product quality stabilizes.

High Specific Surface Area

Specific surface area (SSA), measured in m²/g, is the surface area per unit mass of powder. It is a vital indicator of a material’s reactivity in chemical processes. A larger contact area leads to more complete and controllable synthesis, higher calcium carbonate utilization, and lower powder consumption rate, demonstrating higher activity. Thus, SSA has become a key indicator for the activity of ultra-fine calcium carbonate powder. The ring roller mill can produce ultra-fine powder with a specific surface area of 2.24 m²/g (at D97=10μm).

Upgrading your calcium carbonate processing with a ring roller mill represents a strategic investment in productivity and product superiority. By mastering its non-rigid grinding principle and adhering to key operational practices—such as gradual feeding and proper shutdown procedures—you can maximize yield and ensure consistent D97 < 10μm fineness. The proven benefits of significant cost savings, remarkable energy efficiency, high classification accuracy, operational stability, and superior product activity (high specific surface area) make it an indispensable solution for modern, high-demand applications.

Epic Powder

Epic Powder is specialized in fine powder processing technology for mineral industry, chemical industry, food industry, pharama industry, etc. Our team has more than 20 years experience in Various powders processing.

We are a professional supplier of powder processing projects, especially powder milling, powder classifying, powder dispersing, powder classifying, powder surface treatment and waste recycling. We supply consultancy, testing, project design, machines, commissioning and training.

Ready to transform your fine powder production? Evaluate how the ring roller mill’s advantages in processing ground calcium carbonate align with your capacity and quality goals. Contact us today to explore implementing this efficient technology.

“Thanks for reading. I hope my article helps. Please leave a comment down below.

You may also contact EPIC Powder online customer representative Zelda for any further inquiries.”

— Emily Chen, Senior Engineer